SF6 Gas System For GIS Manufacturers

Applications for Gas insulated switchgear manufacturer

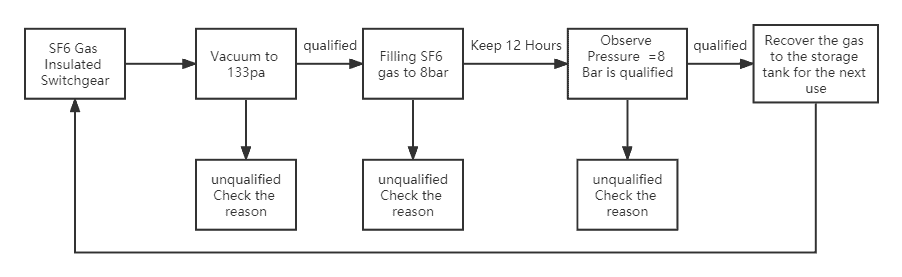

Manufacturers of gas insulated switchgear are required to test each unit for tightness before delivery.

Need a lot of SF6 gas filling into multiple equipment.

When the test is complete and SF6 gas needs to be recovered from the equipment,

For SF6 gas reuse to other equipment.

The gas recovery and filling speed determines the manufacturing speed of the manufacturer

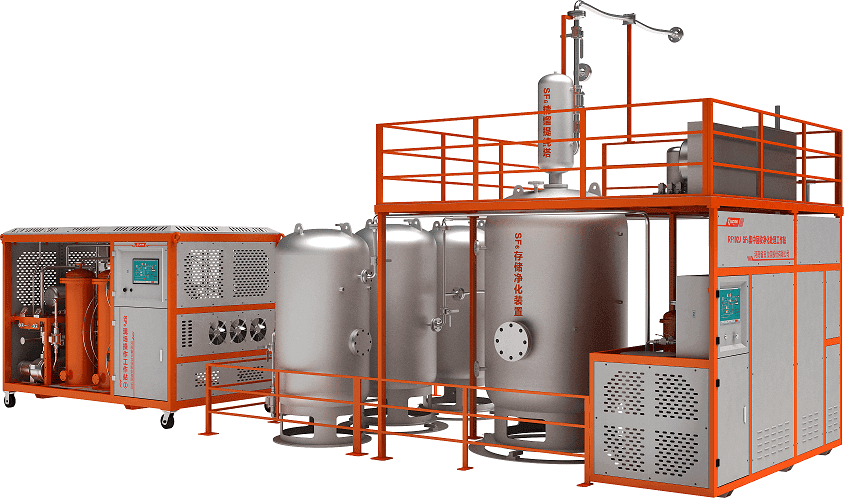

High speed recovery equipment, high-speed filling equipment, and vacuum equipment are what they need

During the test.If there are any leaks in the equipment.The air was contaminated with SF6.

Manufacturers are doing extreme tests. Gas insulated switch discharge test high voltage arc pulling.

Sulfur hexafluoride gas will be high voltage cracking, decomposition of SO2 CF4 and other toxic and harmful gases.

Whether it’s polluted by air or by decomposition products.There are high risks associated with SF6 gas use.

Without gas regeneration system, testing requires the purchase of large amounts of new sulfur hexafluoride gas for use.

High prices are not environmentally friendly

Our product is designed to reuse SF6 gas for Gas Insulated switchgear manufacturers , saving costs .Improved efficiency.and protecting the environment.

Other features:

- 500-2000 m³/h vacuum speed optional

- 1000-5000L Storage tank

- 120KG/h – 240KG/h recovery speed

- SF6 Gas regeneration for IEC 60480 optional